Hey everyone, let’s dive into the world of tire pressure sensors for your Geely MK, specifically the models from TWO THOUSAND AND SIX to TWO THOUSAND AND THIRTEEN. We’re going to cover everything you need to know about installing and programming these vital safety components.

First off, let’s talk about what these sensors actually do. They’re not just some fancy add-on; they’re a crucial part of your vehicle’s safety system. These little guys constantly monitor the air pressure within each tire. Why is this important? Well, under-inflated tires can lead to a whole host of problems. Reduced fuel efficiency is a big one – you’ll be spending more money at the pump. Plus, under-inflation increases the risk of a blowout, which can be incredibly dangerous, especially at higher speeds. And finally, uneven tire pressure can lead to premature tire wear, costing you more in the long run. So, these sensors are all about keeping you safe, saving you money, and extending the life of your tires. They’re a pretty smart investment, if you ask me.

Now, let’s get into the nitty-gritty of the pressure sensor itself. These aren’t your grandpappy’s tire pressure gauges. They’re sophisticated little devices that use radio frequency technology to transmit data wirelessly to your car’s onboard computer. They’re usually small, battery-powered units that are mounted inside the valve stem of each tire. The sensors themselves are pretty robust, designed to withstand the rigors of daily driving, including bumps, potholes, and even the occasional curb rash (though I wouldn’t recommend that!). They’re also sealed to protect the internal electronics from moisture and dirt. Replacing them is usually a straightforward process, but we’ll get into the specifics of that in a moment.

Next up: the placement of the system components. The sensors, as I mentioned, are located inside the valve stems of each tire. The receiver unit, which picks up the signals from the sensors, is usually integrated into the car’s existing electronics system. You won’t see a separate box or anything like that. The information is then processed by the car’s computer, and displayed on your dashboard. This usually involves a simple visual indicator, and sometimes even a numerical readout of the pressure in each tire. Knowing where everything is located will make the installation process much smoother.

Finally, let’s tackle the installation and programming. This is where things get a little more hands-on. First, you’ll need the correct sensors for your Geely MK. Make sure you get the ones specifically designed for your model year. Then, you’ll need to carefully remove the old sensors (if you’re replacing them) and install the new ones. This usually involves using a special tool to remove the valve core, and then carefully screwing the new sensor into place. Once all FOUR sensors are installed, the tricky part comes in: programming. This process varies slightly depending on the specific year and model of your Geely MK. Some models require a specialized scan tool to program the sensors, while others might have a simpler process involving a series of key presses or a specific sequence of actions. I strongly recommend consulting your owner’s manual or a qualified mechanic for the precise programming instructions for your particular vehicle. Getting this step right is crucial for the system to function correctly. Remember, safety first!

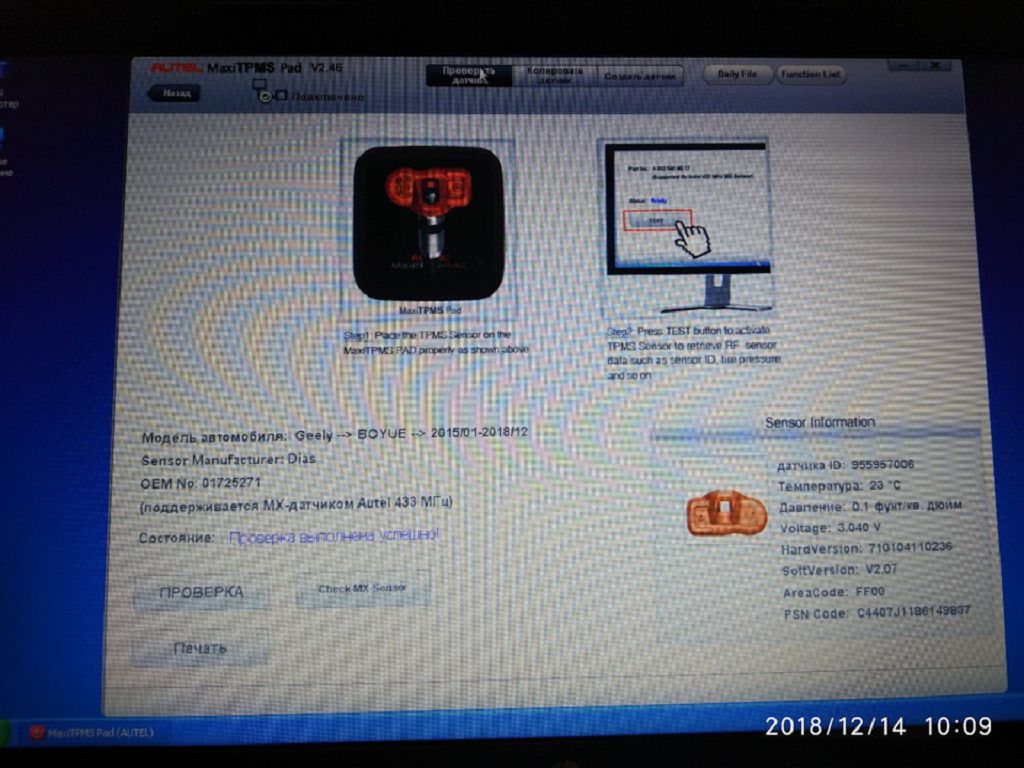

Okay, so let’s dive straight into those tire pressure sensors for your Geely MK, models from TWO THOUSAND AND SIX to TWO THOUSAND AND THIRTEEN. First up, we’ll talk about finding suitable sensor analogs. This is important because sometimes finding the exact OEM part can be a real hassle, and frankly, expensive. There are a lot of reputable aftermarket brands out there that offer sensors that work just as well, often at a fraction of the cost. Now, when you’re looking for an analog, you need to pay close attention to the frequency. Each sensor operates at a specific frequency, and you absolutely MUST match that frequency to your Geely MK’s system. Getting the wrong frequency will mean the sensors won’t communicate with your car’s computer, and your TPMS system won’t work. Also, check the sensor’s valve stem type – make sure it’s compatible with your wheels. There are different types, and using the wrong one can lead to leaks. Don’t just grab the cheapest option; do your research and read reviews to find a reliable and compatible analog. Remember, a faulty sensor is worse than no sensor at all, because it can give you false readings.

Next, let’s get into replacing the sensor itself. This isn’t rocket science, but it does require some care. First, you’ll need the right tools: a tire iron, a valve core removal tool, and possibly a torque wrench to ensure you tighten the new sensor correctly. Before you start, make sure your tires are properly deflated. This makes the whole process safer and easier. Now, carefully remove the old sensor using the valve core removal tool. Once the old sensor is out, you can install the new one. Make sure it’s seated properly and tighten it securely, but don’t overtighten! Overtightening can damage the sensor or the valve stem. Once the new sensor is in, re-inflate your tire to the correct pressure. Remember to check your owner’s manual for the recommended tire pressure for your Geely MK.

Now, let’s talk about disconnecting the sensor. This is usually only necessary if you’re doing some serious wheel work, like changing rims or getting new tires. The process is pretty straightforward. You’ll need to locate the sensor’s connector, usually found near the valve stem. Carefully disconnect the connector, making sure not to damage the wires or the connector itself. Once disconnected, you can safely remove the wheel. When you’re ready to re-install, simply reconnect the sensor. Sometimes, after disconnecting and reconnecting, you might need to reprogram the sensors. This is where things can get a little tricky. Some Geely MK models will automatically relearn the sensor IDs after a short drive, but others might require a specific procedure using a scan tool. If you’re not comfortable doing this yourself, it’s best to take your car to a qualified mechanic. They’ll have the right tools and expertise to get the job done correctly. Remember, safety is paramount, so if you’re unsure about any step, don’t hesitate to seek professional help.