So, we’re here at the HAVAL full-service plant in the Tula region, and this is where the magic happens – the assembly of the Haval Jolion. It’s a pretty impressive facility, and I’m excited to show you around and give you a closer look at the process. Let’s start by talking about the assembly quality. You know, I’ve seen a lot of assembly lines in my time, and what strikes me here is the sheer precision and attention to detail. The workers are incredibly skilled, and the whole process is incredibly streamlined. They’re not just putting parts together; they’re building a vehicle, and you can feel the pride they take in their work. The robots are integrated seamlessly, working alongside the human workforce, ensuring efficiency and accuracy. There’s a real sense of collaboration here, and it’s fascinating to witness. They’re constantly monitoring and improving the process, ensuring that every Jolion rolling off the line meets the highest quality standards. You can see the rigorous quality checks at every stage, from the initial welding to the final inspection. It’s not just about speed; it’s about creating a vehicle that’s reliable, durable, and safe. The level of quality control here is truly remarkable.

Now, let’s move on to the stamping shop. This is where the raw metal sheets are transformed into the body panels of the Jolion. It’s a truly impressive sight – these massive machines are incredibly powerful, yet they operate with incredible precision. Watching these machines work is like witnessing a ballet of industrial might. The sheer scale of the operation is breathtaking. They’re stamping out THOUSANDS of parts every day, all with incredible accuracy and consistency. The noise is something else – it’s a powerful, almost primal sound, a testament to the raw power at work here. But amidst the noise and the power, there’s an incredible level of control and precision. Every single panel is checked for imperfections, ensuring that only the highest quality parts make it to the assembly line. It’s a crucial stage in the process, and it’s clear that no detail is overlooked. The whole process is incredibly efficient, a testament to the advanced technology and skilled workforce employed here. Seeing this firsthand really gives you a new appreciation for the engineering and manufacturing that goes into creating a vehicle like the Haval Jolion. The precision and efficiency are truly remarkable.

Okay, let’s dive right into the heart of the matter: where exactly is the Haval Jolion assembled, and who’s the mastermind behind its creation? We’re going to take a behind-the-scenes look at the manufacturing process, starting with the very beginning.

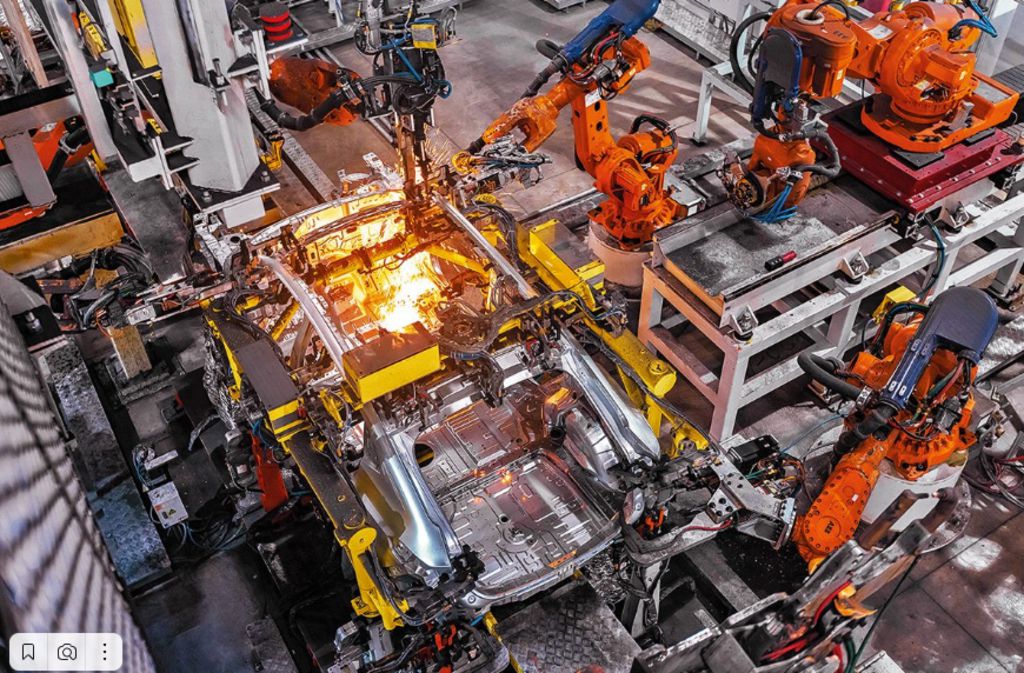

First up, the welding shop. This isn’t just some casual spot-welding operation; this is a high-tech symphony of precision and power. Imagine HUNDREDS of robotic arms, moving with balletic grace, seamlessly joining together the various steel components that form the Jolion’s body. It’s mesmerizing to watch these robots work, each one performing its specific task with incredible accuracy. They’re not just welding; they’re creating the very skeleton of the vehicle, ensuring structural integrity and safety. The level of automation here is truly impressive, minimizing human error and maximizing efficiency. You’ll see the sparks fly, the robots whirring, and the sheer scale of the operation is breathtaking. We’re talking about a massive, highly organized space where the foundation of your Haval Jolion is meticulously built. Think of the precision required – every weld needs to be perfect, strong enough to withstand the rigors of the road, yet lightweight enough to contribute to fuel efficiency. It’s a fascinating process to witness.

Next, we move on to the painting shop. This is where the Jolion gets its personality. After the body is welded, it’s meticulously cleaned and prepared for the painting process. This isn’t just a quick spray job; it’s a multi-stage process involving several coats of primer, base coat, and clear coat. Each coat is applied with precision, ensuring a flawless, even finish. The paint shop is a controlled environment, with strict regulations on temperature and humidity to guarantee the highest quality finish. You’ll see the sheer scale of the operation – rows and rows of car bodies moving through the process, each one slowly transforming from bare metal to its final, vibrant color. The technology used here is amazing; the robots are just as precise in their painting as they were in welding, ensuring a consistent and high-quality finish every single time. And the colors! You’ll see the stunning range of options available for the Haval Jolion, all achieved through this meticulous painting process.

Finally, we arrive at quality control. This is the crucial final stage where every single Jolion undergoes rigorous testing to ensure it meets the highest standards. This isn’t just a quick visual inspection; it involves sophisticated automated systems and meticulous manual checks. Think of it as a comprehensive health check for each vehicle. Every component is examined, every function is tested, to guarantee that the vehicle leaving the factory is not only visually appealing but also safe and reliable. The level of detail is astonishing; they check everything from the engine performance to the functionality of the infotainment system. Nothing escapes their scrutiny. This is where the manufacturer’s commitment to quality truly shines through. It’s a testament to their dedication to producing a vehicle that meets, and even exceeds, customer expectations. Seeing this process firsthand really emphasizes the care and attention to detail that goes into every single Haval Jolion.